Wire rope hoists are among the most widely used lifting devices across industries such as manufacturing, logistics, steel plants, shipyards, and construction. Their ability to handle heavy loads with precision makes them an essential part of safe material handling.

However, not all hoists are built the same. From rope construction to control systems, several specifications determine whether a hoist is safe, efficient, and suitable for your operations. This blog explores 10 must know specifications to consider when choosing wire rope hoists.

1. Capacity & Lift Height

Every hoist is defined by its load capacity and the maximum height it can lift safely. Industry standards emphasize that the selected capacity should not only match current needs but also leave a margin for safety.

Our standard wire rope hoists support capacities from 0.25 to 15 tons, with lift heights reaching up to 16 meters, while our open winch variants extend up to 40 tons and 75 meters. These ranges cover a broad spectrum of industrial applications.

2. Wire Rope Quality & Safety Factor

The wire rope is a critical component, engineered for tensile strength, fatigue resistance, and durability. Industry practice mandates a safety factor of 5:1 for material handling and up to 10:1 in critical applications. At SWIFT, we use galvanized, high-grade wire ropes with heat resistant coatings in selected models to maximize life and reliability.

3. Motor & Gear Mechanism

A reliable hoist depends on a high-torque motor and durable gears. Industrial buyers should look for induction motors, strong gearboxes, and energy-efficient designs. Our wire rope hoists feature compact, high torque induction motors housed inside the drum assembly, paired with hardened steel gears—designed for longevity and consistent performance.

4. Rope Drum & Spooling Design

Improper spooling is one of the most common causes of rope damage. Grooved drums and smooth winding systems keep the rope aligned, extending its life. Our rope drums are precision-engineered to minimize rope crushing and ensure even winding.

5. Control Systems & Speed Regulation

Precise control is a hallmark of modern hoists. SWIFT hoists are outfitted with advanced control systems, including Variable Frequency Drives (VFDs) for micro speed control and panels equipped with overload relays and single-phase preventers. These features support safety and operational efficiency.

6. Safety Standards & Compliance

Compliance ensures both the operator’s safety and regulatory approval. Standards like IS, FEM, and OSHA guidelines cover aspects from load testing to periodic inspections. Our wire rope hoist range adheres to IS and FEM standards, and flame-proof models comply with IS-2148 certifications.

7. Environmental Suitability

Worksites differ some are clean shop floors, others are explosive-prone zones. For hazardous areas, flame-proof hoists are essential. SWIFT’s Flame-Proof Wire Rope Hoist, with capacities up to 10 tons, are certified for explosive atmospheres under IS-2148 and CMRS standards for Groups I, II-A, and II-B gases.

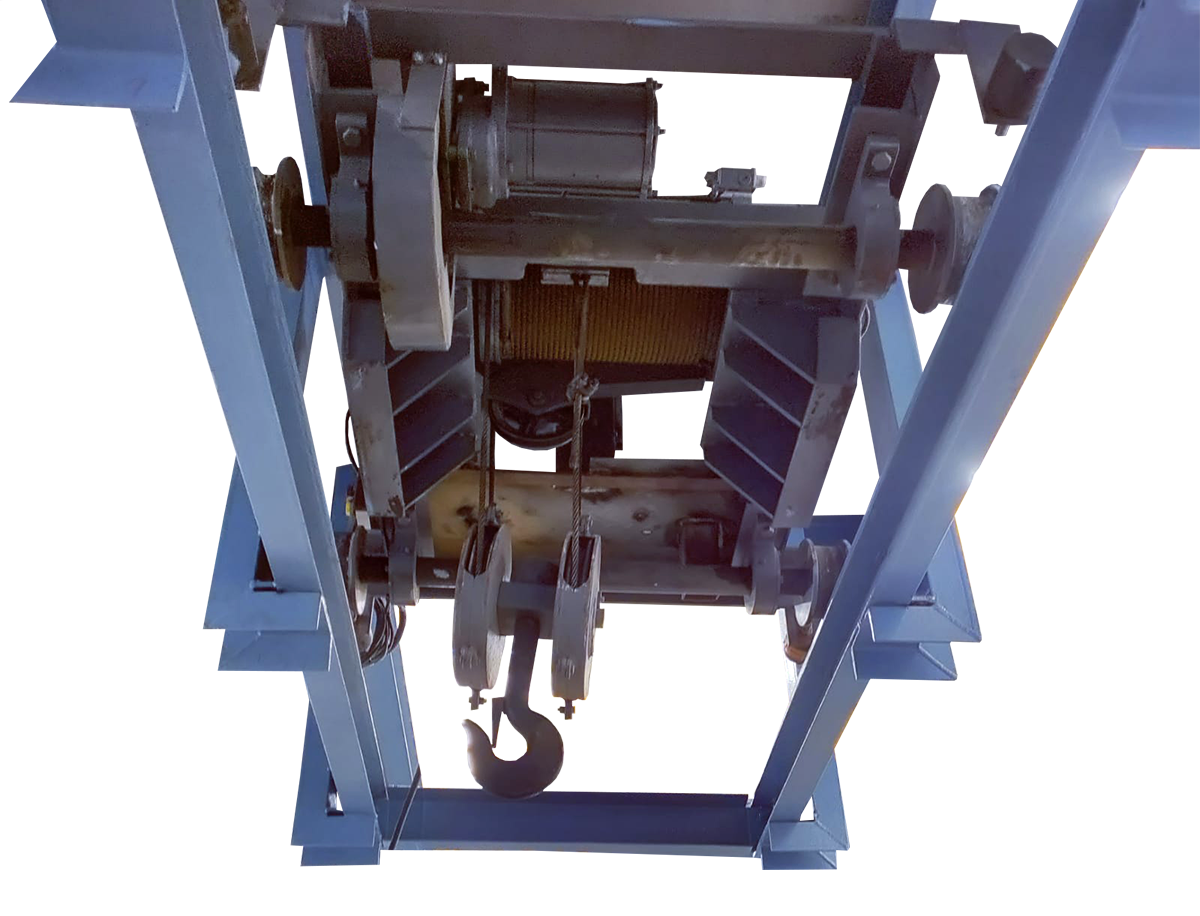

8. Mounting & Headroom Constraints

Adaptability in mounting makes hoists versatile. Our Bi-Rail Crab Hoist is built for double-girder systems up to 10 tons and features fail-safe brakes and compact designs. Further, our Low Headroom (LHR) Hoists enable vertical lifting in tight clearances with swivel trolley options for curved tracks ideal for compact layouts.

9. Maintenance & Serviceability

A hoist is only as reliable as its upkeep. Industry’s best practices include scheduled inspections, availability of spares, and modular components for quick servicing. Our modular designs and robust after-sales support simplify service and ensure minimal operational disruption.

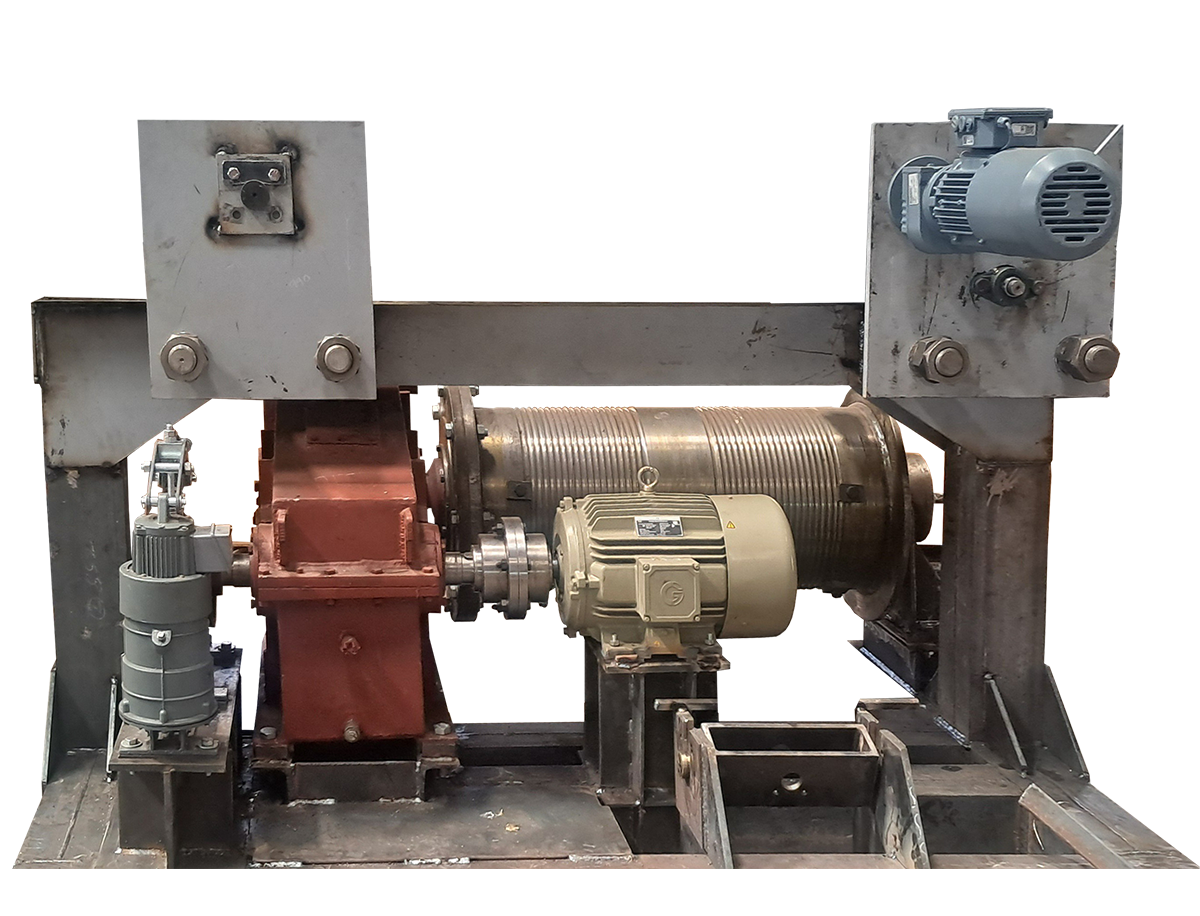

10. Customization & Heavy-Duty Applications

Not all operations are alike customization matters. Heavy-duty industries such as steel, mining, and shipbuilding often need higher capacities with high lifts. SWIFT’s Open Winch Wire Rope Hoist cater to heavy-duty demands lifting up to 40 tons and 75 meters with options for plate or frame types, flame-proofing, and variable speeds. These are engineered for tough operations where one-size-fits-all solutions simply don’t suffice.

Conclusion

Choosing the right wire rope hoist means evaluating not just capacity and height but also rope integrity, control systems, compliance, environmental readiness, customization, and maintainability. With SWIFT’s diverse hoist portfolio from standard to flame-proof to heavy-duty winch types you get equipment engineered for safety, durability, and performance.

For specialized lifting solutions or expert guidance, reach out at:

📩 enquire@csil.in

📞 +91 9403 89 2303

Let SWIFT power your material handling with confidence and excellence.