Oil and Gas

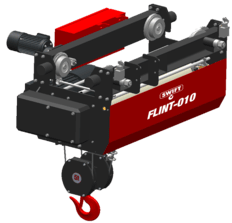

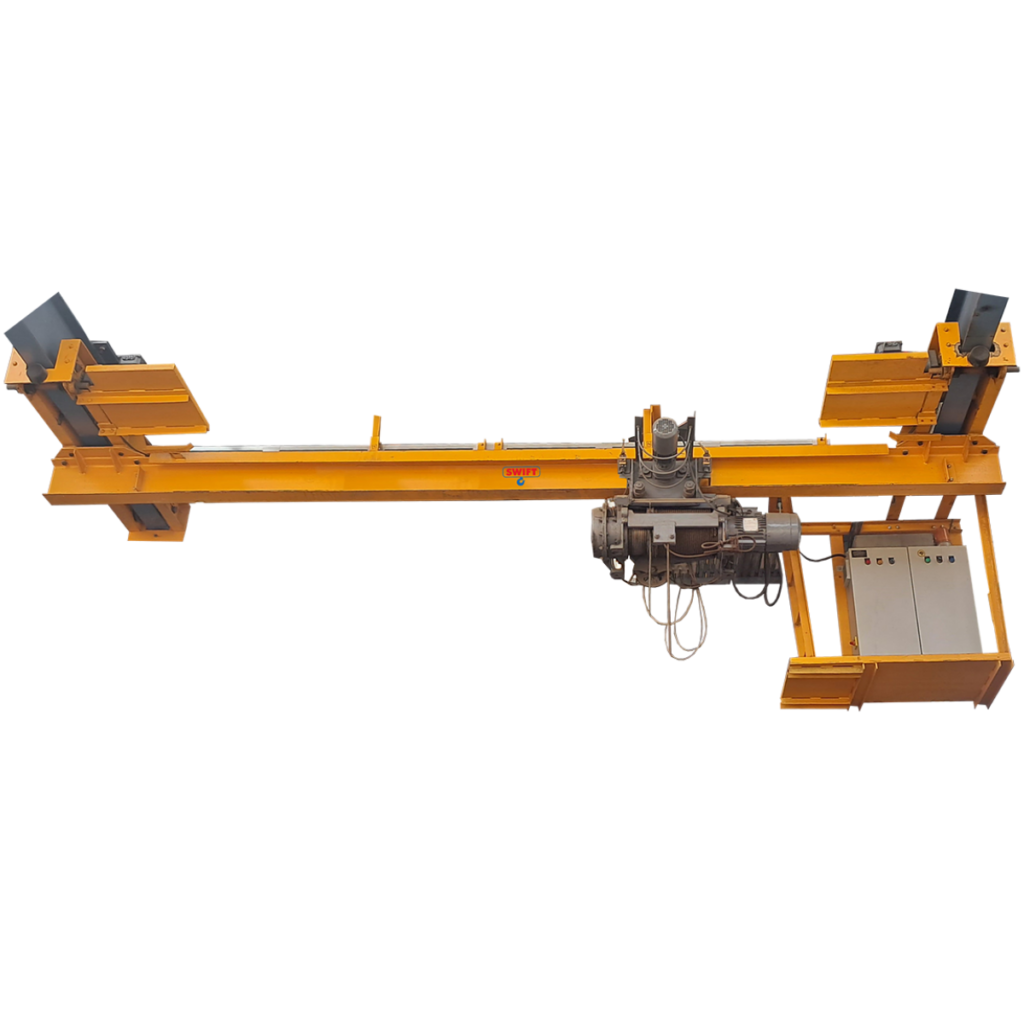

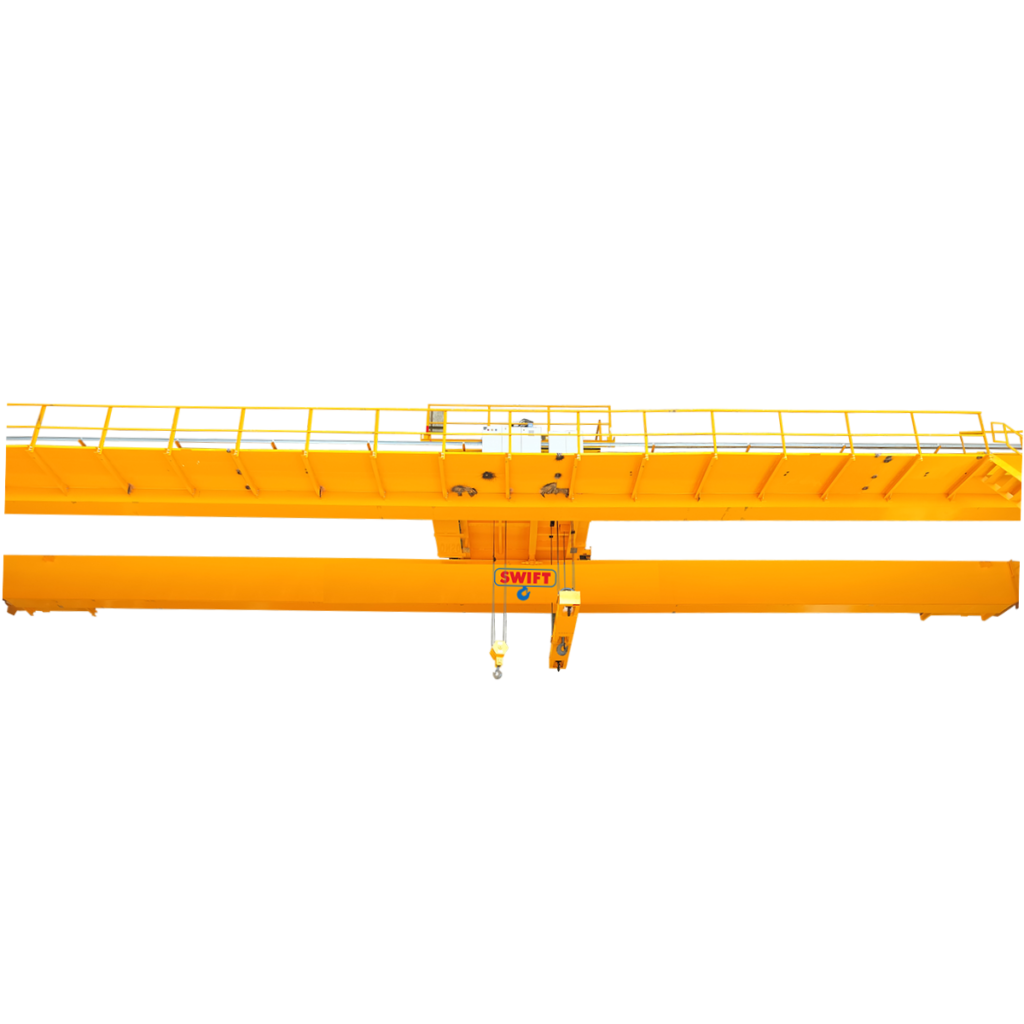

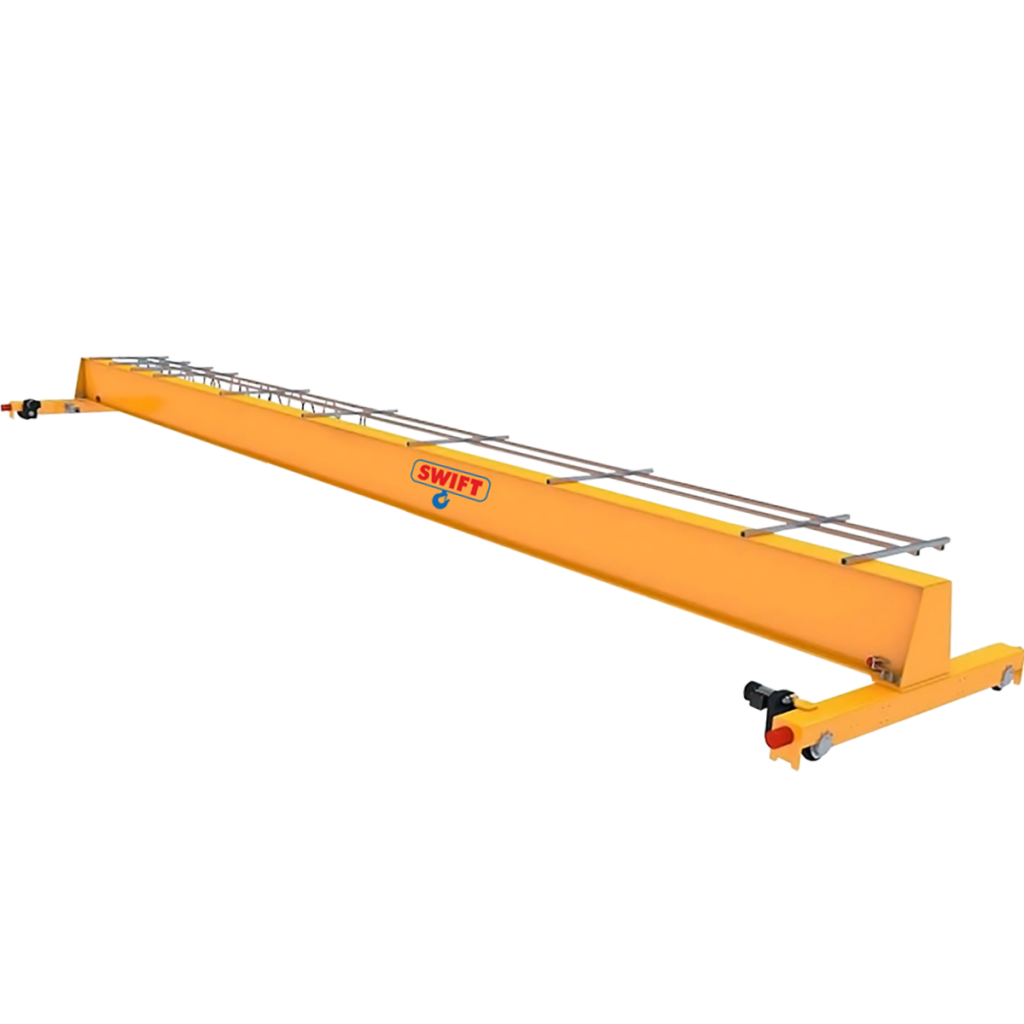

The oil and gas industry continues to expand, requiring material handling solutions that meet stringent safety standards. SWIFT provide a range of flameproof hoists and cranes to meet the safety requirements for such hazardous applications.

Sub Division

Utility Area Shed

We provide material handling solutions designed for safety in hazardous environments (Zone 1, 2, 22), including oil cooling and pumping systems, with equipment built for various gas groups like IIA/IIB/IIC.

Sludge Storage Shed

Handling sludge, a hazardous byproduct from industrial and energy production requires equipment that meets the highest safety standards. SWIFT’s cranes and hoists are designed to ensure reliable performance and minimal downtime in these challenging environments.

Pump Room

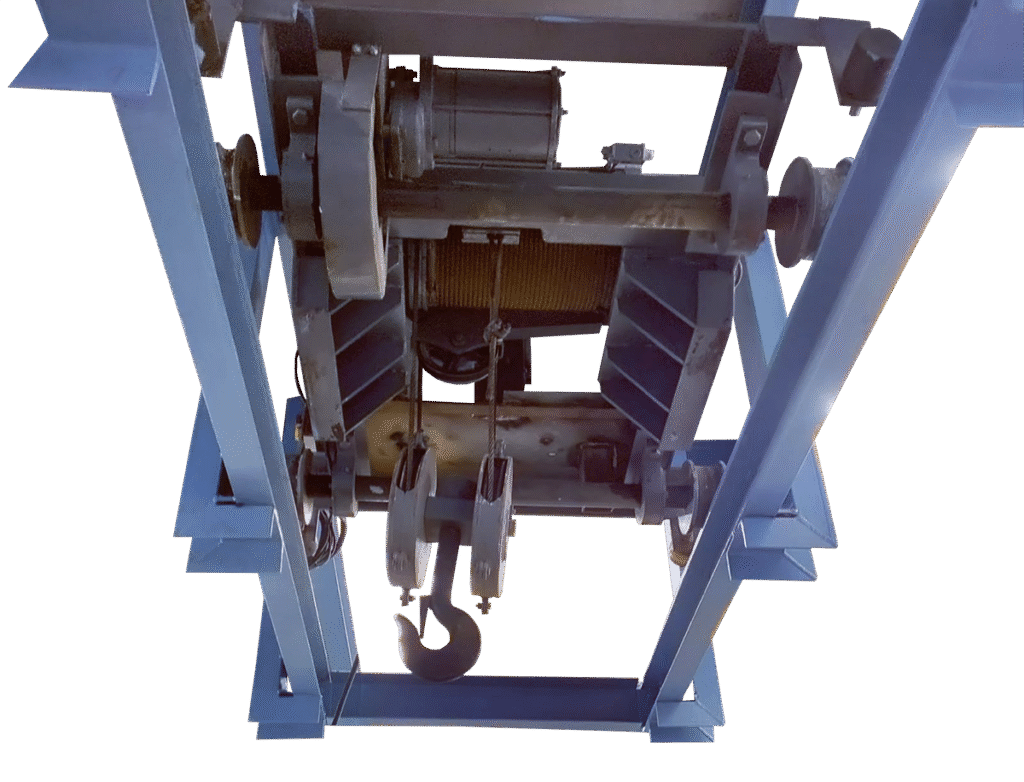

Pump rooms on oil tankers involve significant hazards due to concentrated pipelines. SWIFT provides a range of flameproof hoists and cranes to meet the safety requirements for such hazardous applications.

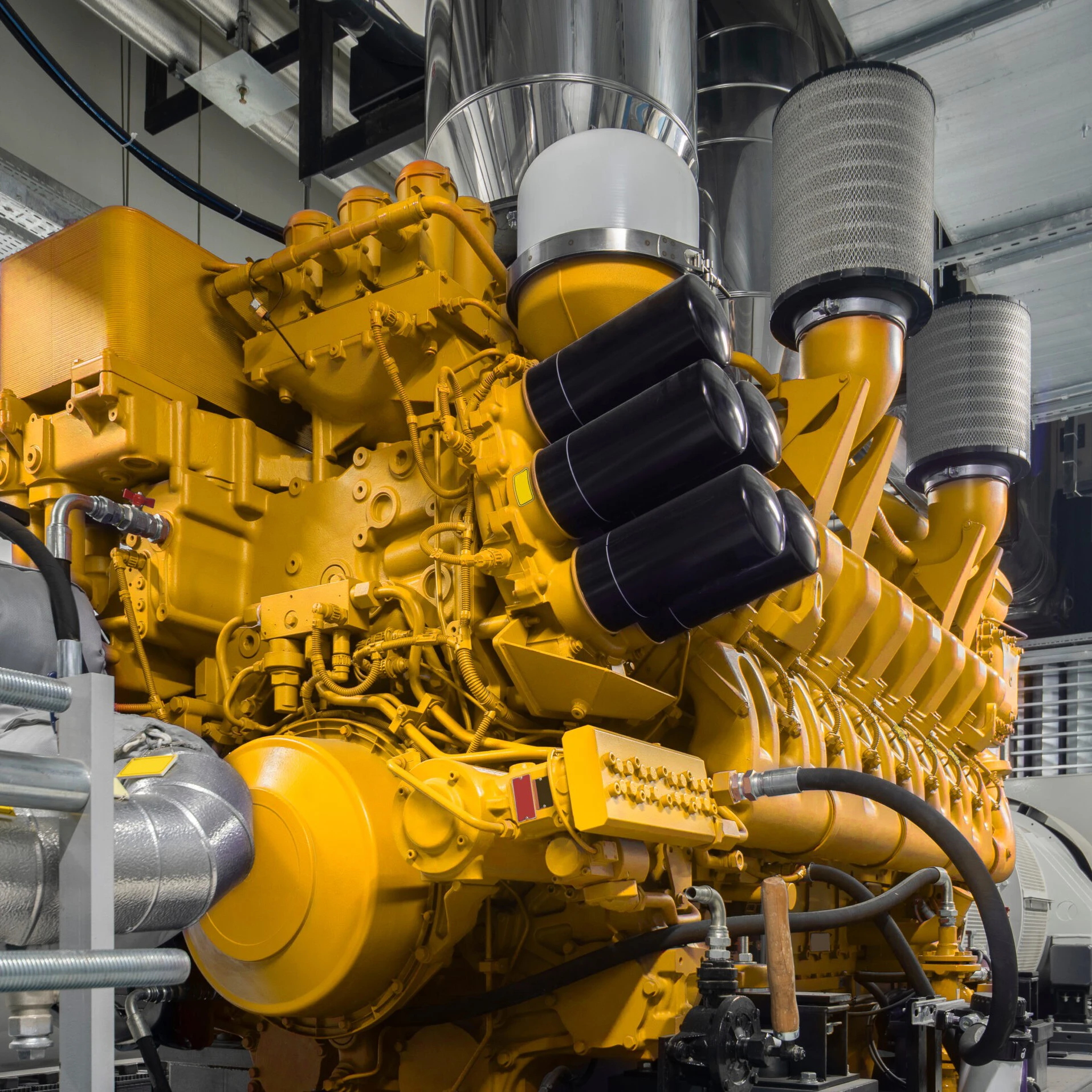

Generator Shed

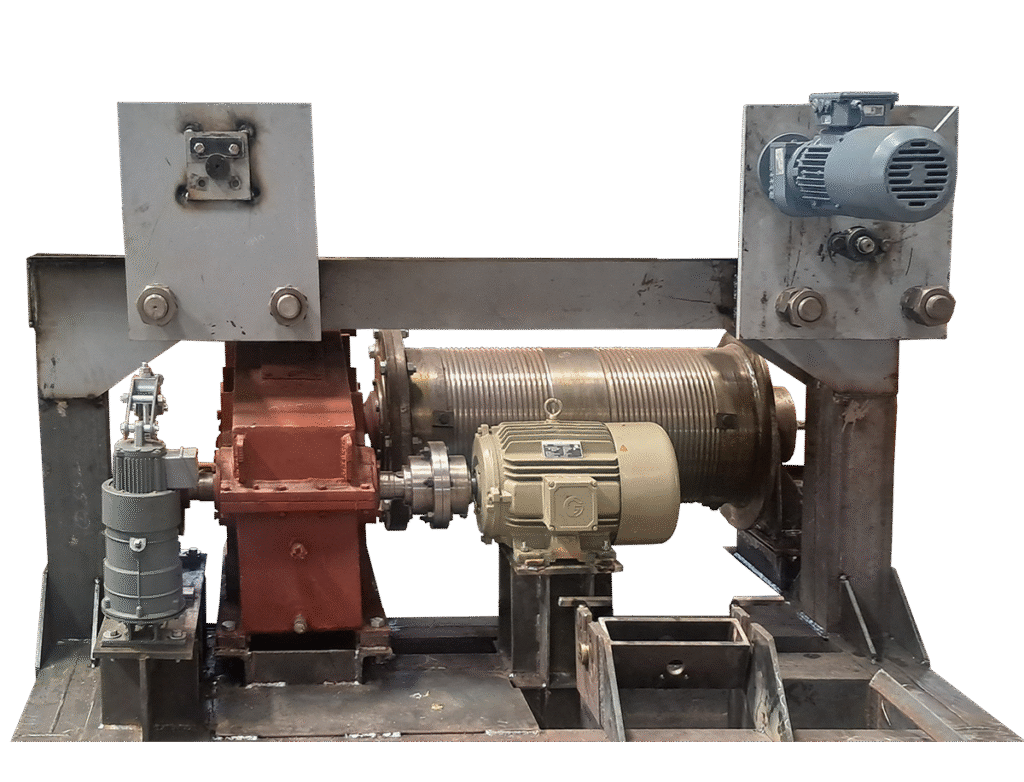

Generator sheds are vital to the oil and gas industry, especially for drilling and digging. Our flameproof solutions cater to all material handling needs, ensuring reliable operations.

Chemical House

In environments with high ambient conditions, such as chemical houses, SWIFT provides specialized flameproof hoists, and cranes to ensure safe and efficient operation.

Borewell Room

For deep drilling operations, SWIFT’s flameproof hoists provide essential support, ensuring efficiency and safety in hazardous zones.