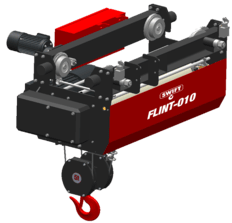

FLINT Wire Rope Hoist

At SWIFT, we design hoisting solutions that combine engineering precision with operational efficiency. The FLINT Wire Rope Hoist is a compact and robust lifting system, engineered to deliver superior performance for single-girder, box-type, electrically operated cranes. Built for demanding industrial applications, it offers high lifting reliability with optimized space utilization—making it ideal for workshops, assembly lines, and process plants.

Available in capacities ranging from 1 ton to 10 tons, with lift heights of 6, 9, and 12 meters, the FLINT hoist features a lightweight FEM-engineered structure that minimizes girder load while maintaining exceptional strength. Its optimized drum and reeving design reduce headroom and side clearances, ensuring maximum hook approach within tight working spaces. Tested to IS 3938 and FEM 9.511 standards, the FLINT guarantees reliability and long-term performance in every lift.