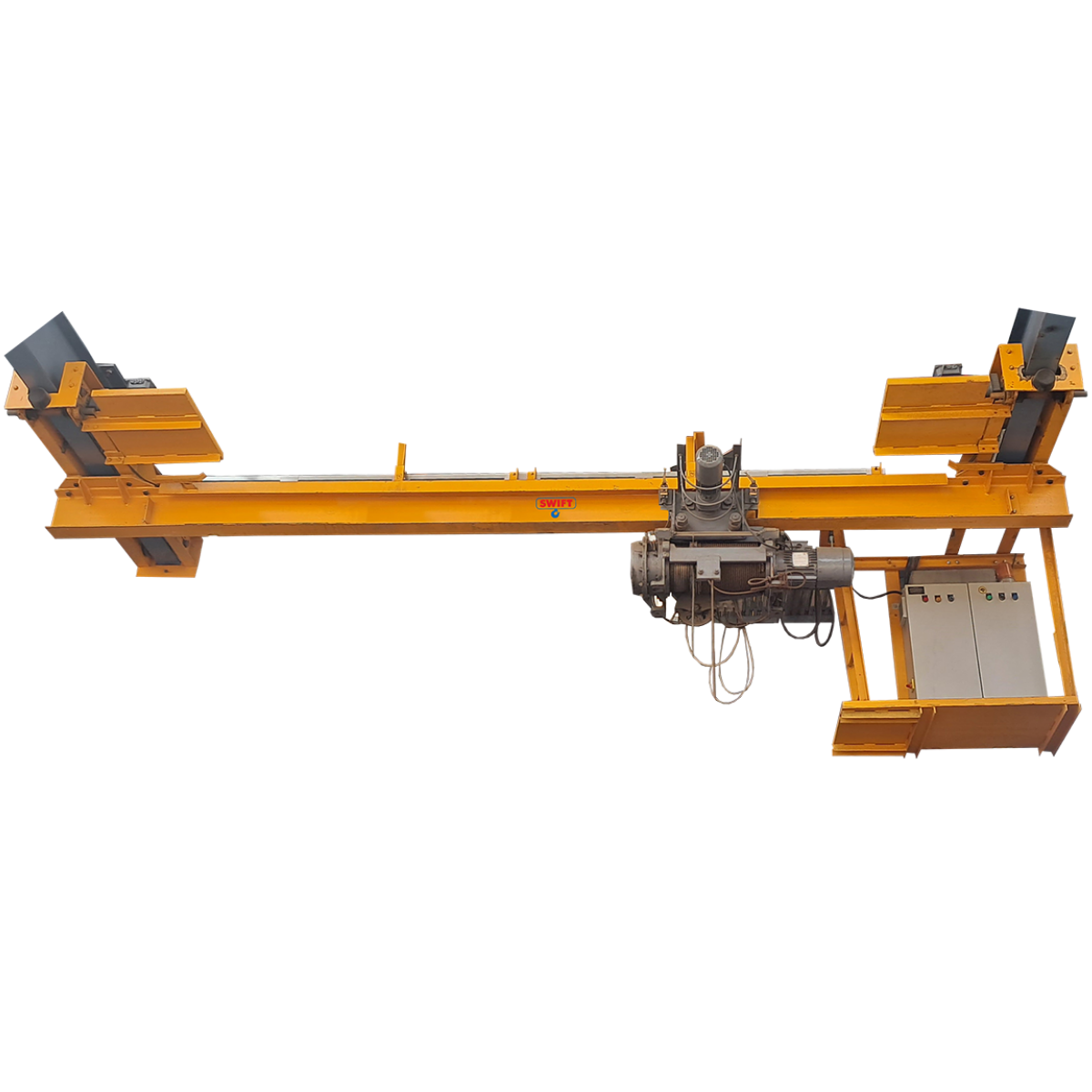

Single Girder Underslung E.O.T. Crane

Our Single Girder Underslung E.O.T. Cranes are engineered to provide versatile lifting in environments where ceiling height or structural limitations prevent the installation of standard overhead cranes. These cranes run on the bottom flange of runway beams, making them ideal for low-headroom areas and lighter structural frameworks. With safe working loads from 0.5 tons to 40 tons and spans up to 30 meters, they offer a space-saving and structurally adaptable solution for diverse material handling needs.