When it comes to efficient material handling, Electric Overhead Travelling (EOT) cranes remain one of the most reliable solutions across industries. From warehouses and workshops to heavy-duty manufacturing units and shipyards, EOT cranes are designed to handle loads with precision, safety, and speed.

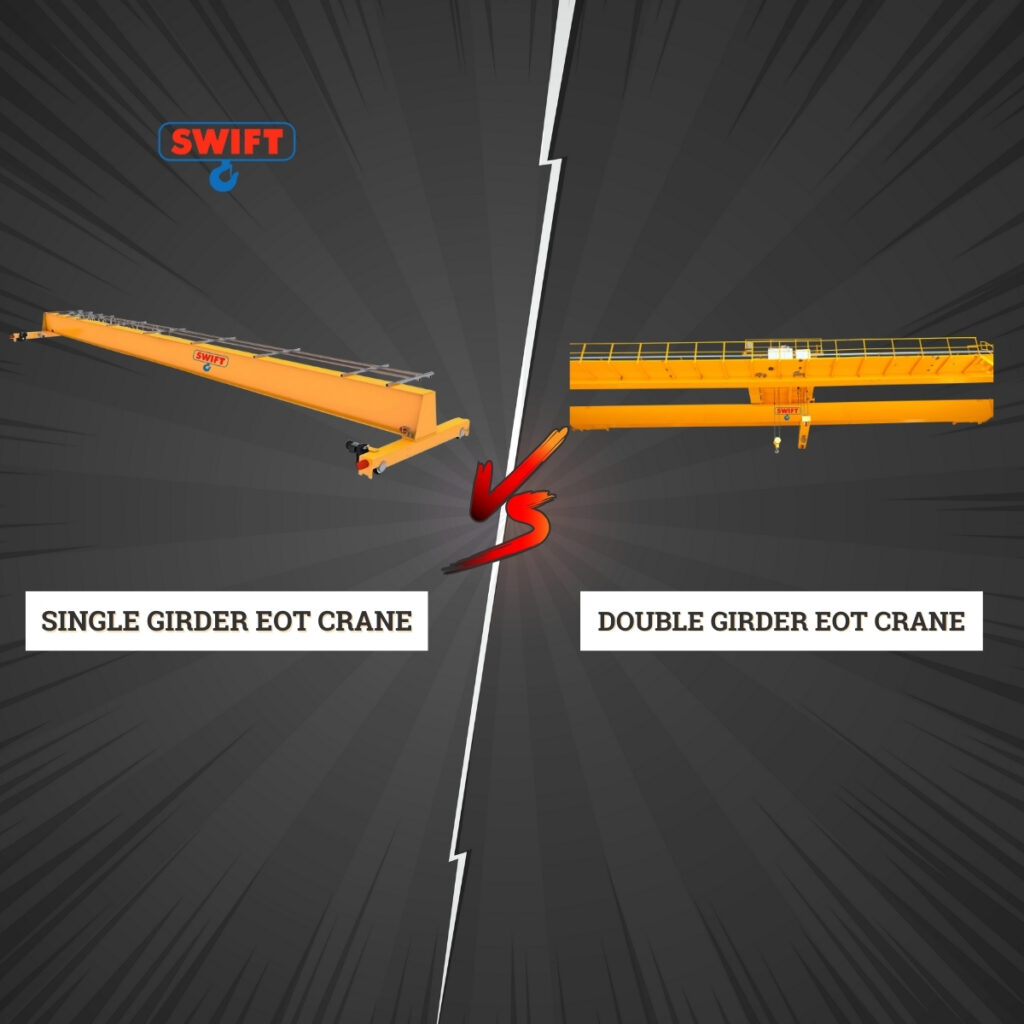

But when you’re evaluating your options, the big question often is: Should you go for a single girder or a double girder crane? Both have their unique advantages, and the right choice depends on your load requirements, available space, budget, and operational needs.

This blog breaks down the key differences between single girder and double girder cranes, helping you identify which one best fits your workspace.

Understanding the Basics

What is a Single Girder EOT Crane?

A single girder crane uses one bridge girder with a hoist that travels on the bottom flange of the girder. These cranes are compact, economical, and suitable for light to medium-duty applications.

Our Single Girder EOT Cranes offer safe working loads up to 35 tons with spans of up to 30 meters. They can be installed in both overhead and underslung configurations, making them versatile for different industrial layouts.

What is a Double Girder EOT Crane?

A double girder crane uses two bridge girders, with the hoist running on rails placed on top. This design provides higher strength, greater lifting height, and better load distribution—ideal for heavy-duty and large-span applications.

Our Double Girder EOT Cranes support safe working loads from 2 tons to 60 tons (and up to 100 tons as per requirement), with spans up to 32 meters. These cranes are equipped with bi-rail crab hoists for efficient and robust performance.

8 Key Comparison Points

1. Load Capacity

-

Single Girder: Best suited for lighter operations, with typical capacities up to 35 tons.

-

Double Girder: Handles heavy-duty lifting, commonly used for loads above 20 tons, with SWIFT models going up to 100 tons.

Key Takeaway: If your operations involve extremely heavy loads, double girder cranes are the safer and more reliable choice.

2. Span and Coverage

-

Single Girder: Works efficiently for spans up to 30 meters.

-

Double Girder: Can handle longer spans of up to 32 meters and beyond.

Key Takeaway: For wider workspaces, double girder cranes provide greater reach without compromising stability.

3. Lifting Height

-

Single Girder: Offers a standard lift height suitable for most workshops.

-

Double Girder: Since the hoist sits on top of the girders, it offers greater lifting height, making it ideal for tall buildings or plants with vertical storage.

4. Design & Construction

-

Single Girder: Compact design with lighter construction, often using rolled I-beams or box-type girders.

-

Double Girder: Heavy-duty box-type girders provide additional strength, with a service platform for easier maintenance.

Key Takeaway: If you have limited headroom, single girder cranes fit better; for rugged, continuous use, double girders excel.

5. Cost Efficiency

-

Single Girder: More economical in terms of purchase, installation, and maintenance costs.

-

Double Girder: Higher initial investment due to additional steel, components, and motorized features.

Key Takeaway: Budget-sensitive operations usually prefer single girders, while businesses needing long-term heavy lifting invest in double girders.

6. Maintenance Access

-

Single Girder: Maintenance can be slightly challenging as there’s no full-length service platform.

-

Double Girder: Provides easy access with service platforms running along the girders, simplifying inspection and repairs.

7. Operational Features

Both our crane types offer customization with options like:

-

Anti-collision systems

-

Load limiters and indicators

-

Remote controls

-

Alarm systems and bridge lights

However, our double girder cranes often come with more advanced features such as anti-sway mechanisms and variable frequency drives (VFDs) for smoother, controlled movements.

8. Applications

-

Single Girder: Best for light-to-medium duty industries such as small workshops, fabrication units, and warehouses.

-

Double Girder: Designed for heavy-duty industries including steel plants, shipyards, foundries, and large-scale manufacturing.

When to Choose Single Girder EOT Cranes

-

You need cost-effective lifting solutions.

-

Load requirements are within 0.5 to 35 tons.

-

Available headroom is limited, and a compact design is necessary.

-

Your workspace involves short to medium spans.

When to Choose Double Girder EOT Cranes

-

Your facility requires high-capacity lifting (20 tons and above).

-

You need to cover larger spans with greater lifting height.

-

Easy maintenance access is a priority.

-

The application involves continuous heavy-duty operations.

SWIFT’s Advantage

At SWIFT, we design both single and double girder EOT cranes with features that prioritize safety, reliability, and efficiency.

-

Single Girder EOT Cranes – Compact, versatile, and customizable with optional features like anti-collision systems, load indicators, and radio remote controls.

-

Double Girder EOT Cranes – Rugged, modular, and tailored for heavy-duty applications, with customizable speeds, advanced braking, and service-friendly designs.

Our cranes comply with Indian and international standards, ensuring long-term performance and safety in every lift.

Conclusion

Choosing between a single girder and a double girder EOT crane depends entirely on your operational needs—whether it’s load capacity, span, height, or budget considerations. Single girder cranes provide compact, economical solutions for lighter tasks, while double girder cranes are the powerhouse choice for heavy-duty, high-capacity lifting.

At SWIFT, we help you make the right choice by offering a complete range of EOT cranes, tailored to your workspace and industry.

📩 For enquiries, write to us at: enquire@csil.in

📞 Call us at: +91 9403 89 2303

Your workspace deserves a crane that matches its demands—let SWIFT guide you to the right solution.