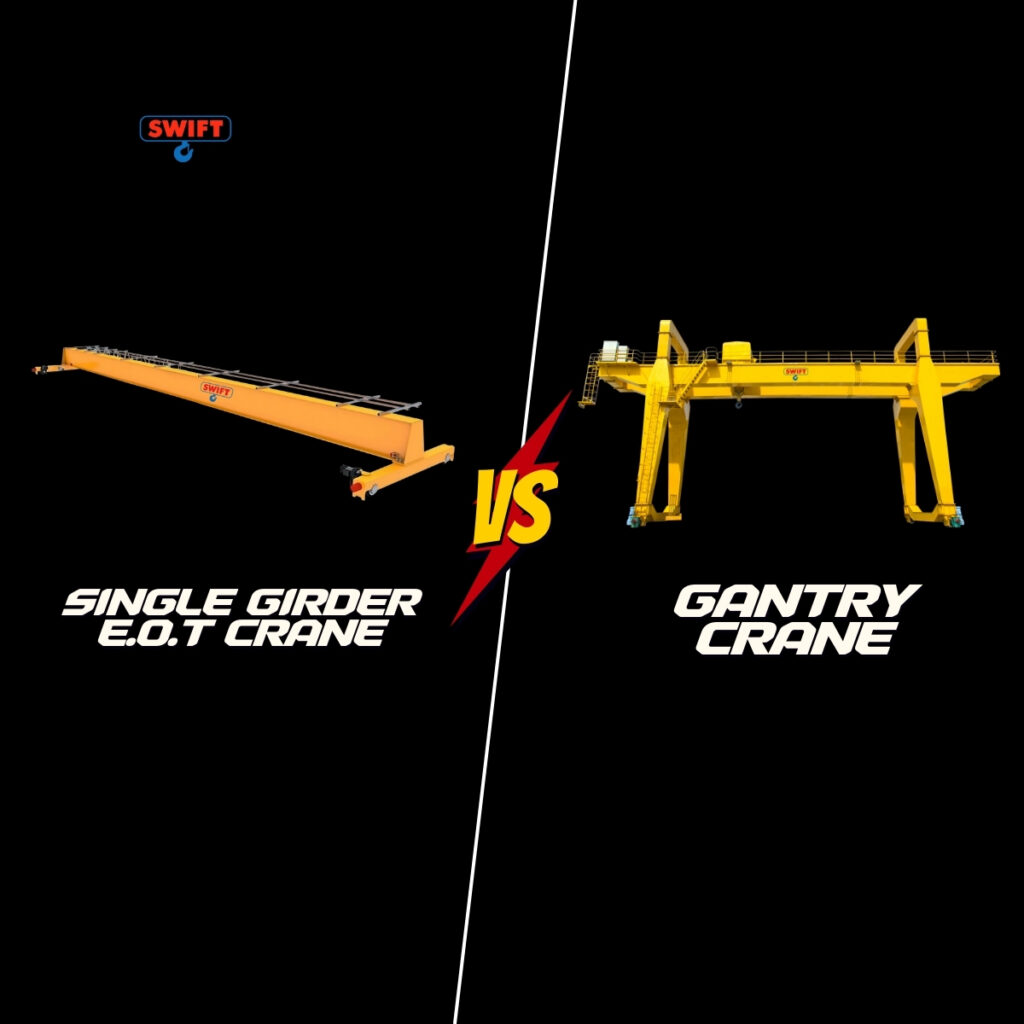

When it comes to material handling in industrial environments, cranes are indispensable. They streamline lifting, moving, and positioning heavy loads, ensuring efficiency and safety in operations. But not all cranes are created equal. Among the most widely used are Gantry Cranes and EOT Cranes.

While both are designed to handle heavy lifting, they differ significantly in structure, applications, and benefits. Choosing the right one depends on your specific operational requirements, budget, and facility setup. In this blog, we’ll break down 8 key comparison points between gantry cranes and EOT cranes to help you make an informed decision.

1. Structural Design

EOT Crane: Installed permanently inside a building, EOT cranes run on rails fixed to elevated runways along the walls or ceiling. They are integrated into the facility’s structure, making them ideal for long-term usage.

Gantry Crane: Instead of fixed runways, gantry cranes use freestanding legs that move on wheels or rails. They can be positioned indoors or outdoors, offering more flexibility in terms of relocation.

Key Takeaway: If you need a permanent, high-capacity lifting solution inside a plant, an EOT crane is better. For flexible or temporary setups, a gantry crane is the right choice.

2. Installation Requirements

EOT Crane: Requires significant structural preparation. The building must be reinforced to support runway beams, making installation more complex and costly.

Gantry Crane: Simpler to install since it does not rely on building structures. Many models are portable, requiring less infrastructure modification.

Key Takeaway: Gantry cranes win in terms of easier and more cost-effective installation.

3. Mobility and Flexibility

EOT Crane: Fixed in place, suitable only for lifting operations along the runway path. Relocation or expansion requires substantial investment.

Gantry Crane: Portable models can be moved within a facility or even outdoors. This flexibility makes them ideal for shipyards, construction sites, or where lifting needs shift frequently.

Key Takeaway: Gantry cranes provide unmatched mobility.

4. Capacity and Size

EOT Crane: Can handle extremely heavy loads, ranging from a few tons to hundreds of tons, depending on design. They are built for continuous, high-capacity operations in steel plants, automotive factories, and heavy engineering.

Gantry Crane: Usually designed for lighter to medium loads, although heavy-duty gantry cranes exist. Capacities typically range from 1 ton to about 100 tons, depending on the model.

Key Takeaway: For maximum load capacity, EOT cranes are superior.

5. Indoor vs. Outdoor Applications

EOT Crane: Best suited for indoor use, especially in manufacturing plants and warehouses. Outdoor usage is limited unless specifically engineered for weather resistance.

Gantry Crane: Performs well both indoors and outdoors. It’s commonly used in shipyards, rail yards, and construction projects due to its adaptability to varied environments.

Key Takeaway: Gantry cranes are more versatile for outdoor lifting.

6. Space Utilization

EOT Crane: Operates at ceiling level, leaving floor space free for other activities. This makes them highly efficient for facilities with limited floor area.

Gantry Crane: Requires floor space for its supporting legs and rails. While some portable designs minimize obstruction, they still occupy ground space.

Key Takeaway: EOT cranes win in terms of maximizing floor space.

7. Maintenance and Durability

EOT Crane: With fewer moving components exposed to outdoor conditions, EOT cranes typically require less frequent maintenance and have a longer lifespan if used indoors.

Gantry Crane: Outdoor operation exposes them to weather elements, increasing wear and tear. Regular inspection and maintenance are critical to ensure safe performance.

Key Takeaway: EOT cranes tend to offer better long-term durability in controlled environments.

8. Cost Considerations

EOT Crane: Higher upfront costs due to installation, structural reinforcement, and customization. However, the investment pays off in high-capacity, continuous-duty operations.

Gantry Crane: Generally more affordable, with lower installation costs and quicker setup. Portable gantry cranes are cost-effective solutions for small to medium lifting needs.

Key Takeaway: For budget-conscious buyers or temporary applications, gantry cranes are more cost-efficient. For large-scale, long-term operations, EOT cranes justify their higher investment.

Which Crane Should You Choose?

The decision between a gantry crane and an EOT crane depends on your priorities:

Choose an EOT Crane if:

You require high-capacity lifting on a permanent basis.

You want to maximize floor space.

Your operations are confined to an indoor facility.

Choose a Gantry Crane if:

You need a versatile crane for indoor and outdoor use.

You require mobility and flexibility in lifting operations.

You prefer lower installation costs and quicker setup.

SWIFT’s Expertise in Crane Solutions

At SWIFT, we design and manufacture cranes that balance performance, safety, and cost-effectiveness. Whether you’re looking for a robust EOT crane for high-capacity lifting or a flexible gantry crane for versatile applications, our solutions are engineered to meet international safety standards and deliver reliable performance across industries.

Our team works closely with you to understand your operational needs and recommend the right lifting solution for your facility—ensuring that every investment you make in material handling equipment is both safe and productive.

Conclusion

Both gantry and EOT cranes play vital roles in industrial lifting. By evaluating the 8 comparison points—design, installation, mobility, capacity, application, space utilization, maintenance, and cost—you can make a decision that best suits your needs.

At SWIFT, we are committed to providing crane solutions that combine reliability with efficiency, tailored to your industry.

📩 For enquiries, write to us at: enquire@csil.in

📞 Call us at: +91 9403 89 2303

Your lifting operations deserve equipment that aligns with your goals—whether it’s flexibility, capacity, or efficiency. Let SWIFT be your partner in choosing the right crane solution.